Product Description

Product Description

| model | Number of poles | Phase | Rated voltage | Rated speed | Continuous locked-rotor torque | Rated torque | Rated power | Peak torque |

| Units | VDC | RPM | N.m | N.m | W | N.m | ||

| 42BYA075B030C-02 | 4 | 3 | 24 | 3000 | 0.192 | 0.16 | 50 | 0.48 |

| model | Peak current | Torque constant | Back EMF | Motor length | Motor length | voltage range | Range of rotation | weight |

| Units | A | Nm/A | V/KRPM | g.cMoment of inertia | mm | VDC | RPM | Kg |

| 42BYA075B030C-02 | 9.6 | 0.05 | 3.947 | 14.6 | 134 | 24~48 | 1000~3000 | 1.0 |

Product Parameters

Quiet stable and reliable for long life operation

1.Voltage: 24 VDC

2.Number of phases: 3

3.Number of levels: 4

4.Line-to-line resistance: 1.45±10%ohms

5.Line-to-line inductance: 1.27±20%mH

6.Rated current: 3.2A

7.Rated power: 50W

8.No-load speed: 4300 rpm

9.Insulation class: B

10.Reduction ratio: 1:58.22

11.Output torque: 7.5 N.m

12.Output speed: 51.5 rpm

13.We can design the special voltage and shaft and so on

| Application: | Industrial |

|---|---|

| Speed: | High Speed |

| Number of Stator: | Three-Phase |

| Function: | Driving, Control |

| Casing Protection: | Protection Type |

| Number of Poles: | 8 |

| Samples: |

US$ 162/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

The Basics of a Planetary Motor

A Planetary Motor is a type of gearmotor that uses multiple planetary gears to deliver torque. This system minimizes the chances of failure of individual gears and increases output capacity. Compared to the planetary motor, the spur gear motor is less complex and less expensive. However, a spur gear motor is generally more suitable for applications requiring low torque. This is because each gear is responsible for the entire load, limiting its torque.

Self-centering planetary gears

This self-centering mechanism for a planetary motor is based on a helical arrangement. The helical structure involves a sun-planet, with its crown and slope modified. The gears are mounted on a ring and share the load evenly. The helical arrangement can be either self-centering or self-resonant. This method is suited for both applications.

A helical planetary gear transmission is illustrated in FIG. 1. A helical configuration includes an output shaft 18 and a sun gear 18. The drive shaft extends through an opening in the cover to engage drive pins on the planet carriers. The drive shaft of the planetary gears can be fixed to the helical arrangement or can be removable. The transmission system is symmetrical, allowing the output shaft of the planetary motor to rotate radially in response to the forces acting on the planet gears.

A flexible pin can improve load sharing. This modification may decrease the face load distribution, but increases the (K_Hbeta) parameter. This effect affects the gear rating and life. It is important to understand the effects of flexible pins. It is worth noting that there are several other disadvantages of flexible pins in helical PGSs. The benefits of flexible pins are discussed below.

Using self-centering planetary gears for a helical planetary motor is essential for symmetrical force distribution. These gears ensure the symmetry of force distribution. They can also be used for self-centering applications. Self-centering planetary gears also guarantee the proper force distribution. They are used to drive a planetary motor. The gearhead is made of a ring gear, and the output shaft is supported by two ball bearings. Self-centering planetary gears can handle a high torque input, and can be suited for many applications.

To solve for a planetary gear mechanism, you need to find its pitch curve. The first step is to find the radius of the internal gear ring. A noncircular planetary gear mechanism should be able to satisfy constraints that can be complex and nonlinear. Using a computer, you can solve for these constraints by analyzing the profile of the planetary wheel’s tooth curve.

High torque

Compared to the conventional planetary motors, high-torque planetary motors have a higher output torque and better transmission efficiency. The high-torque planetary motors are designed to withstand large loads and are used in many types of applications, such as medical equipment and miniature consumer electronics. Their compact design makes them suitable for small space-saving applications. In addition, these motors are designed for high-speed operation.

They come with a variety of shaft configurations and have a wide range of price-performance ratios. The FAULHABER planetary gearboxes are made of plastic, resulting in a good price-performance ratio. In addition, plastic input stage gears are used in applications requiring high torques, and steel input stage gears are available for higher speeds. For difficult operating conditions, modified lubrication is available.

Various planetary gear motors are available in different sizes and power levels. Generally, planetary gear motors are made of steel, brass, or plastic, though some use plastic for their gears. Steel-cut gears are the most durable, and are ideal for applications that require a high amount of torque. Similarly, nickel-steel gears are more lubricated and can withstand a high amount of wear.

The output torque of a high-torque planetary gearbox depends on its rated input speed. Industrial-grade high-torque planetary gearboxes are capable of up to 18000 RPM. Their output torque is not higher than 2000 nm. They are also used in machines where a planet is decelerating. Their working temperature ranges between 25 and 100 degrees Celsius. For best results, it is best to choose the right size for the application.

A high-torque planetary gearbox is the most suitable type of high-torque planetary motor. It is important to determine the deceleration ratio before buying one. If there is no product catalog that matches your servo motor, consider buying a close-fitting high-torque planetary gearbox. There are also high-torque planetary gearboxes available for custom-made applications.

High efficiency

A planetary gearbox is a type of mechanical device that is used for high-torque transmission. This gearbox is made of multiple pairs of gears. Large gears on the output shaft mesh with small gears on the input shaft. The ratio between the big and small gear teeth determines the transmittable torque. High-efficiency planetary gearheads are available for linear motion, axial loads, and sterilizable applications.

The AG2400 high-end gear unit series is ideally matched to Beckhoff’s extensive line of servomotors and gearboxes. Its single-stage and multi-stage transmission ratios are highly flexible and can be matched to different robot types. Its modified lubrication helps it operate in difficult operating conditions. These high-performance gear units are available in a wide range of sizes.

A planetary gear motor can be made of steel, nickel-steel, or brass. In addition to steel, some models use plastic. The planetary gears share work between multiple gears, making it easy to transfer high amounts of power without putting a lot of stress on the gears. The gears in a planetary gear motor are held together by a movable arm. High-efficiency planetary gear motors are more efficient than traditional gearmotors.

While a planetary gear motor can generate torque, it is more efficient and cheaper to produce. The planetary gear system is designed with all gears operating in synchrony, minimizing the chance of a single gear failure. The efficiency of a planetary gearmotor makes it a popular choice for high-torque applications. This type of motor is suitable for many applications, and is less expensive than a standard geared motor.

The planetary gearbox is a combination of a planetary type gearbox and a DC motor. The planetary gearbox is compact, versatile, and efficient, and can be used in a wide range of industrial environments. The planetary gearbox with an HN210 DC motor is used in a 22mm OD, PPH, and ph configuration with voltage operating between 6V and 24V. It is available in many configurations and can be custom-made to meet your application requirements.

High cost

In general, planetary gearmotors are more expensive than other configurations of gearmotors. This is due to the complexity of their design, which involves the use of a central sun gear and a set of planetary gears which mesh with each other. The entire assembly is enclosed in a larger internal tooth gear. However, planetary motors are more effective for higher load requirements. The cost of planetary motors varies depending on the number of gears and the number of planetary gears in the system.

If you want to build a planetary gearbox, you can purchase a gearbox for the motor. These gearboxes are often available with several ratios, and you can use any one to create a custom ratio. The cost of a gearbox depends on how much power you want to move with the gearbox, and how much gear ratio you need. You can even contact your local FRC team to purchase a gearbox for the motor.

Gearboxes play a major role in determining the efficiency of a planetary gearmotor. The output shafts used for this type of motor are usually made of steel or nickel-steel, while those used in planetary gearboxes are made from brass or plastic. The former is the most durable and is best for applications that require high torque. The latter, however, is more absorbent and is better at holding lubricant.

Using a planetary gearbox will allow you to reduce the input power required for the stepper motor. However, this is not without its downsides. A planetary gearbox can also be replaced with a spare part. A planetary gearbox is inexpensive, and its spare parts are inexpensive. A planetary gearbox has low cost compared to a planetary motor. Its advantages make it more desirable in certain applications.

Another advantage of a planetary gear unit is the ability to handle ultra-low speeds. Using a planetary gearbox allows stepper motors to avoid resonance zones, which can cause them to crawl. In addition, the planetary gear unit allows for safe and efficient cleaning. So, whether you’re considering a planetary gear unit for a particular application, these gear units can help you get exactly what you need.

editor by CX 2023-06-01

China High quality central chain dc brushless motor 48V60V72V motor efficiency

Guarantee: 3months-1year

Design Quantity: LYH-1

Use: Electric powered Bicycle

Kind: Brushless Motor

Torque: 3

Commutation: Brushless

Defend Feature: Waterproof

Velocity(RPM): 3200

Continuous Existing(A): 4.5

Effectiveness: IE 2

Application: Tricycle

Motor type: Bushless

Rated Voltage: 48v/60v/72v

Electrical power: 1500W

Feature: High Effectiveness

Sounds: Reduced Sounds Level

Purpose: Sorts

MOQ: 1 Pcs

Packaging Details: Normal export deal for 62mm dc bldc gear motor

Port: ZheJiang , HangZhou, HangZhou,HangZhou

Substantial top quality electric tricycle dc motor 48V/60V/72V voltage 1500W/1800W/2200W/2500W/3000W energy Specification

| Rated output electricity | 1500w | 1800w | 2200w |

| Rated voltage | forty eight/60/72v DC | forty eight/sixty/72v DC | 48/sixty/72v DC |

| Rated rotating speed | 3000RPM | 3000RPM | 3000RPM |

| No-load speed | 3700RPM | 4300RPM | 4800RPM |

| Rated recent | < DC 12V Micro motor RS385 9800RPM CCW motors for hairdryer electric toothbrush splay stand brush machine 39/31/26A | <37.5/31.5A | <46/38A |

| No-load current | <6/5.5/4.5A | < High quality 57 integrated closed-loop stepping motor 1.2Nm 2Nm 2.5Nm 3Nm 6/5.5A | <6/5.5A |

| ARated torque | 5.2N.M | 6.0N.M | seven.2N.M |

| Eff | >82% | >83% | > 1 aluminium single split shaft locking collars 1 piece clamp-on shaft collars with oxidize 84% |

How to Assemble a Planetary Motor

A Planetary Motor uses multiple planetary surfaces to produce torque and rotational speed. The planetary system allows for a wide range of gear reductions. Planetary systems are particularly effective in applications where higher torques and torque density are needed. As such, they are a popular choice for electric vehicles and other applications where high-speed mobility is required. Nevertheless, there are many benefits associated with using a planetary motor. Read on to learn more about these motors.

VPLite

If you’re looking to replace the original VP, the VPLite has a similar output shaft as the original. This means that you can mix and match your original gear sets, including the input and output shafts. You can even mix metal inputs with plastic outputs. Moreover, if you decide to replace the gearbox, you can easily disassemble the entire unit and replace it with a new one without losing any output torque.

Compared to a planetary motor, a spur gear motor uses fewer gears and is therefore cheaper to produce. However, the latter isn’t suitable for high-torque applications. The torque produced by a planetary gearmotor is evenly distributed, which makes it ideal for applications that require higher torque. However, you may have to compromise on the torque output if you’re looking for a lightweight option.

The VersaPlanetary Lite gearbox replaces the aluminum ring gear with a 30% glass-filled nylon gear. This gearbox is available in two sizes, which means you can mix and match parts to get a better gear ratio. The VPLite gearbox also has a female 5mm hex output shaft. You can mix and match different gearboxes and planetary gearboxes for maximum efficiency.

VersaPlanetary

The VersaPlanetary is a highly versatile planetary motor that can be mounted in a variety of ways. Its unique design includes a removable shaft coupler system that makes it simple to swap out the motor with another. This planetary motor mounts in any position where a CIM motor mounts. Here’s how to assemble the motor. First, remove the hex output shaft from the VersaPlanetary output stage. Its single ring clip holds it in place. You can use a drill press to drill a hole into the output shaft.

After mounting the gearbox, you can then mount the motor. The mounting hardware included with the VersaPlanetary Planetary Motor comes with four 10-32 threaded holes on a two-inch bolt circle. You can use these holes to mount your VersaPlanetary on a CIM motor or a CIM-compatible motor. Once assembled, the VersaPlanetary gearbox has 72 different gear ratios.

The VersaPlanetary gearbox is interchangeable with regular planetary gearboxes. However, it does require additional parts. You can purchase a gearbox without the motor but you’ll need a pinion. The pinion attaches to the shaft of the motor. The gearbox is very sturdy and durable, so you won’t have to worry about it breaking or wearing out.

Self-centering planetary gears

A planetary motor is a simple mechanical device that rotates around a axis, with the planets moving around the shaft in a radial direction. The planets are positioned so that they mesh with both the sun gear and the output gears. The carrier 48 is flexibly connected to the drive shaft and can move depending on the forces exerted by the planet gears. In this way, the planets can always be in the optimal mesh with the output gears and sun gear.

The first step in developing a planetary gear motor is to identify the number of teeth in each planet. The number of teeth should be an integer. The tooth diameters of the planets should mesh with each other and the ring. Typically, the teeth of one planet must mesh with each other, but the spacing between them must be equal or greater than the other. This can be achieved by considering the tooth count of each planet, as well as the spacing between planets.

A second step is to align the planet gears with the output gears. In a planetary motor, self-centering planetary gears must be aligned with both input and output gears to provide maximum torque. For this to be possible, the planet gears must be connected with the output shaft and the input shaft. Similarly, the output shaft should also be able to align with the input gear.

Encoders

A planetary geared motor is a DC motor with a planetary gearbox. The motor can be used to drive heavy loads and has a ratio of 104:1. The shaft speed is 116rpm when it is unloaded. A planetary gearbox has a low backlash and is often used in applications that need high torque. Planetary Motor encoders can help you keep track of your robot’s position or speed.

They are also able to control motor position and speed with precision. Most of them feature high resolution. A 0.18-degree resolution encoder will give you a minimum of 2000 transitions per rotation between outputs A and B. The encoder is built to industrial standards and has a sturdy gearbox to avoid damage. The encoder’s robust design means it will not stall when the motor reaches its maximum speed.

There are many advantages to a planetary motor encoder. A high-quality one will not lose its position or speed even if it’s subject to shocks. A good quality planetary motor will also last a long time. Planetary motors are great for resale or for your own project. If you’re considering buying a planetary motor, consider this information. It’ll help you decide if a particular model is right for your needs.

Cost

There are several advantages of planetary motors. One of the biggest is their cost, but they can also be used in many different applications. They can be combined with a variety of gearboxes, and are ideal for various types of robots, laboratory automation, and production applications. Planetary gearboxes are available in many different materials, and plastic planetary gearboxes are an economical alternative. Plastic gearboxes reduce noise at higher speeds, and steel input stage gears are available for high torques. A modified lubrication system can help with difficult operating conditions.

In addition to being more durable, planetary motors are much more efficient. They use fewer gears, which lowers the overall cost of production. Depending on the application, a planetary motor can be used to move a heavy object, but is generally less expensive than its counterpart. It is a better choice for situations where the load is relatively low and the motor is not used frequently. If you need a very high torque output, a planetary motor may be the better option.

Planetary gear units are a good choice for applications requiring high precision, high dynamics, and high torque density. They can be designed and built using TwinCAT and TC Motion Designer, and are delivered as complete motor and gear unit assemblies. In a few simple steps, you can calculate the torque required and compare the costs of different planetary gear units. You can then choose the best model for your application. And because planetary gear units are so efficient, they are a great option for high-end industrial applications.

Applications

There are several different applications of the planetary motor. One such application is in motion control. Planetary gearboxes have many benefits, including high torque, low backlash, and torsional stiffness. They also have an extremely compact design, and can be used for a variety of applications, from rack and pinion drives to delta robotics. In many cases, they are less expensive to manufacture and use than other types of motors.

Another application for planetary gear units is in rotary tables. These machines require high precision and low backlash for their precise positioning. Planetary gears are also necessary for noise reduction, which is a common feature in rotary tables. High precision planetary gears can make the height adjustment of OP tables a breeze. And because they are extremely durable and require low noise, they are a great choice for this application. In this case, the planetary gear is matched with an AM8000 series servomotor, which gives a wide range of choices.

The planetary gear transmission is also widely used in helicopters, automobiles, and marine applications. It is more advanced than a countershaft drive, and is capable of higher torque to weight ratios. Other advantages include its compact design and reduced noise. A key concern in the development of this type of transmission is to minimize vibration. If the output of a planetary gear transmission system is loud, the vibration caused by this type of drive system may be too loud for comfort.

editor by czh 2023-02-19

China 12V 24V 48V Variable Speed High Power Electric Car Brushless DC Planetary Gear Servo Motor for Micro Electric Pump Fan Chain Grinder with high quality

Solution Description

Product Description

| design | Number of poles | Period | Rated voltage | Rated speed | Constant locked-rotor torque | Rated torque | Rated electrical power | Peak torque |

| Units | VDC | RPM | N.m | N.m | W | N.m | ||

| 42BYA075B030C-02 | 4 | three | 24 | 3000 | .192 | .16 | 50 | .forty eight |

| design | Peak current | Torque consistent | Again EMF | Motor length | Motor length | voltage variety | Range of rotation | fat |

| Models | A | Nm/A | V/KRPM | g.cMoment of inertia | mm | VDC | RPM | Kg |

| 42BYA075B030C-02 | 9.6 | .05 | 3.947 | fourteen.six | 134 | 24~forty eight | one thousand~3000 | one.0 |

Solution Parameters

Tranquil secure and trustworthy for extended life operation

1.Voltage: 24 VDC

2.Variety of phases: three

3.Quantity of amounts: four

four.Line-to-line resistance: 1.45±10%ohms

five.Line-to-line inductance: 1.27±20%mH

6.Rated existing: 3.2A

seven.Rated electrical power: 50W

8.No-load pace: 4300 rpm

nine.Insulation class: B

10.Reduction ratio: 1:58.22

11.Output torque: 7.5 N.m

twelve.Output speed: 51.5 rpm

thirteen.We can design the unique voltage and shaft and so on

|

US $85-130 / Piece | |

50 Pieces (Min. Order) |

###

| Application: | Industrial |

|---|---|

| Speed: | High Speed |

| Number of Stator: | Three-Phase |

| Function: | Driving, Control |

| Casing Protection: | Protection Type |

| Number of Poles: | 8 |

###

| Samples: |

US$ 162/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| model | Number of poles | Phase | Rated voltage | Rated speed | Continuous locked-rotor torque | Rated torque | Rated power | Peak torque |

| Units | VDC | RPM | N.m | N.m | W | N.m | ||

| 42BYA075B030C-02 | 4 | 3 | 24 | 3000 | 0.192 | 0.16 | 50 | 0.48 |

###

| model | Peak current | Torque constant | Back EMF | Motor length | Motor length | voltage range | Range of rotation | weight |

| Units | A | Nm/A | V/KRPM | g.cMoment of inertia | mm | VDC | RPM | Kg |

| 42BYA075B030C-02 | 9.6 | 0.05 | 3.947 | 14.6 | 134 | 24~48 | 1000~3000 | 1.0 |

|

US $85-130 / Piece | |

50 Pieces (Min. Order) |

###

| Application: | Industrial |

|---|---|

| Speed: | High Speed |

| Number of Stator: | Three-Phase |

| Function: | Driving, Control |

| Casing Protection: | Protection Type |

| Number of Poles: | 8 |

###

| Samples: |

US$ 162/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| model | Number of poles | Phase | Rated voltage | Rated speed | Continuous locked-rotor torque | Rated torque | Rated power | Peak torque |

| Units | VDC | RPM | N.m | N.m | W | N.m | ||

| 42BYA075B030C-02 | 4 | 3 | 24 | 3000 | 0.192 | 0.16 | 50 | 0.48 |

###

| model | Peak current | Torque constant | Back EMF | Motor length | Motor length | voltage range | Range of rotation | weight |

| Units | A | Nm/A | V/KRPM | g.cMoment of inertia | mm | VDC | RPM | Kg |

| 42BYA075B030C-02 | 9.6 | 0.05 | 3.947 | 14.6 | 134 | 24~48 | 1000~3000 | 1.0 |

Dynamic Modeling of a Planetary Motor

A planetary gear motor consists of a series of gears rotating in perfect synchrony, allowing them to deliver torque in a higher output capacity than a spur gear motor. Unlike the planetary motor, spur gear motors are simpler to build and cost less, but they are better for applications requiring lower torque output. That is because each gear carries the entire load. The following are some key differences between the two types of gearmotors.

planetary gear system

A planetary gear transmission is a type of gear mechanism that transfers torque from one source to another, usually a rotary motion. Moreover, this type of gear transmission requires dynamic modeling to investigate its durability and reliability. Previous studies included both uncoupled and coupled meshing models for the analysis of planetary gear transmission. The combined model considers both the shaft structural stiffness and the bearing support stiffness. In some applications, the flexible planetary gear may affect the dynamic response of the system.

In a planetary gear device, the axial end surface of the cylindrical portion is rotatable relative to the separating plate. This mechanism retains lubricant. It is also capable of preventing foreign particles from entering the planetary gear system. A planetary gear device is a great choice if your planetary motor’s speed is high. A high-quality planetary gear system can provide a superior performance than conventional systems.

A planetary gear system is a complex mechanism, involving three moving links that are connected to each other through joints. The sun gear acts as an input and the planet gears act as outputs. They rotate about their axes at a ratio determined by the number of teeth on each gear. The sun gear has 24 teeth, while the planet gears have three-quarters that ratio. This ratio makes a planetary motor extremely efficient.

planetary gear train

To predict the free vibration response of a planetary motor gear train, it is essential to develop a mathematical model for the system. Previously, static and dynamic models were used to study the behavior of planetary motor gear trains. In this study, a dynamic model was developed to investigate the effects of key design parameters on the vibratory response. Key parameters for planetary gear transmissions include the structure stiffness and mesh stiffness, and the mass and location of the shaft and bearing supports.

The design of the planetary motor gear train consists of several stages that can run with variable input speeds. The design of the gear train enables the transmission of high torques by dividing the load across multiple planetary gears. In addition, the planetary gear train has multiple teeth which mesh simultaneously in operation. This design also allows for higher efficiency and transmittable torque. Here are some other advantages of planetary motor gear trains. All these advantages make planetary motor gear trains one of the most popular types of planetary motors.

The compact footprint of planetary gears allows for excellent heat dissipation. High speeds and sustained performances will require lubrication. This lubricant can also reduce noise and vibration. But if these characteristics are not desirable for your application, you can choose a different gear type. Alternatively, if you want to maintain high performance, a planetary motor gear train will be the best choice. So, what are the advantages of planetary motor gears?

planetary gear train with fixed carrier train ratio

The planetary gear train is a common type of transmission in various machines. Its main advantages are high efficiency, compactness, large transmission ratio, and power-to-weight ratio. This type of gear train is a combination of spur gears, single-helical gears, and herringbone gears. Herringbone planetary gears have lower axial force and high load carrying capacity. Herringbone planetary gears are commonly used in heavy machinery and transmissions of large vehicles.

To use a planetary gear train with a fixed carrier train ratio, the first and second planets must be in a carrier position. The first planet is rotated so that its teeth mesh with the sun’s. The second planet, however, cannot rotate. It must be in a carrier position so that it can mesh with the sun. This requires a high degree of precision, so the planetary gear train is usually made of multiple sets. A little analysis will simplify this design.

The planetary gear train is made up of three components. The outer ring gear is supported by a ring gear. Each gear is positioned at a specific angle relative to one another. This allows the gears to rotate at a fixed rate while transferring the motion. This design is also popular in bicycles and other small vehicles. If the planetary gear train has several stages, multiple ring gears may be shared. A stationary ring gear is also used in pencil sharpener mechanisms. Planet gears are extended into cylindrical cutters. The ring gear is stationary and the planet gears rotate around a sun axis. In the case of this design, the outer ring gear will have a -3/2 planet gear ratio.

planetary gear train with zero helix angle

The torque distribution in a planetary gear is skewed, and this will drastically reduce the load carrying capacity of a needle bearing, and therefore the life of the bearing. To better understand how this can affect a gear train, we will examine two studies conducted on the load distribution of a planetary gear with a zero helix angle. The first study was done with a highly specialized program from the bearing manufacturer INA/FAG. The red line represents the load distribution along a needle roller in a zero helix gear, while the green line corresponds to the same distribution of loads in a 15 degree helix angle gear.

Another method for determining a gear’s helix angle is to consider the ratio of the sun and planet gears. While the sun gear is normally on the input side, the planet gears are on the output side. The sun gear is stationary. The two gears are in engagement with a ring gear that rotates 45 degrees clockwise. Both gears are attached to pins that support the planet gears. In the figure below, you can see the tangential and axial gear mesh forces on a planetary gear train.

Another method used for calculating power loss in a planetary gear train is the use of an auto transmission. This type of gear provides balanced performance in both power efficiency and load capacity. Despite the complexities, this method provides a more accurate analysis of how the helix angle affects power loss in a planetary gear train. If you’re interested in reducing the power loss of a planetary gear train, read on!

planetary gear train with spur gears

A planetary gearset is a type of mechanical drive system that uses spur gears that move in opposite directions within a plane. Spur gears are one of the more basic types of gears, as they don’t require any specialty cuts or angles to work. Instead, spur gears use a complex tooth shape to determine where the teeth will make contact. This in turn, will determine the amount of power, torque, and speed they can produce.

A two-stage planetary gear train with spur gears is also possible to run at variable input speeds. For such a setup, a mathematical model of the gear train is developed. Simulation of the dynamic behaviour highlights the non-stationary effects, and the results are in good agreement with the experimental data. As the ratio of spur gears to spur gears is not constant, it is called a dedendum.

A planetary gear train with spur gears is a type of epicyclic gear train. In this case, spur gears run between gears that contain both internal and external teeth. The circumferential motion of the spur gears is analogous to the rotation of planets in the solar system. There are four main components of a planetary gear train. The planet gear is positioned inside the sun gear and rotates to transfer motion to the sun gear. The planet gears are mounted on a joint carrier that is connected to the output shaft.

planetary gear train with helical gears

A planetary gear train with helical teeth is an extremely powerful transmission system that can provide high levels of power density. Helical gears are used to increase efficiency by providing a more efficient alternative to conventional worm gears. This type of transmission has the potential to improve the overall performance of a system, and its benefits extend far beyond the power density. But what makes this transmission system so appealing? What are the key factors to consider when designing this type of transmission system?

The most basic planetary train consists of the sun gear, planet gear, and ring gear elements. The number of planets varies, but the basic structure of planetary gears is similar. A simple planetary geartrain has the sun gear driving a carrier assembly. The number of planets can be as low as two or as high as six. A planetary gear train has a low mass inertia and is compact and reliable.

The mesh phase properties of a planetary gear train are particularly important in designing the profiles. Various parameters such as mesh phase difference and tooth profile modifications must be studied in depth in order to fully understand the dynamic characteristics of a PGT. These factors, together with others, determine the helical gears’ performance. It is therefore essential to understand the mesh phase of a planetary gear train to design it effectively.

editor by czh 2022-12-15

China supplier Hollow pin chain with Hot selling

| MAXTOP CHAIN NO. | Pitch | Width | Roller | Plate | Pin | Average | Approx Weight | |||||||

| (ANSI) | Ultimate | kg/m | ||||||||||||

| P | W | Dia | Height | Thickness | Dia | Lengths | Strength | |||||||

| inch | mm | mm | R | H1 | H2 | T1 | T2 | D | d(min) | F | G | kgf | ||

| 40HP | 1/2″ | 12.7 | 7.94 | 7.92 | 10.2 | 11.8 | 1.5 | 1.5 | 5.58 | 4 | 7.9 | 9.4 | 1300 | 0.5 |

| 50HP | 5/8″ | 15.88 | 9.53 | 10.16 | 13 | 14.8 | 2 | 2 | 7.01 | 5.12 | 9.9 | 11.65 | 2000 | 0.8 |

| 60HP | 3/4″ | 19.05 | 12.7 | 11.91 | 15.5 | 17.5 | 2.4 | 2.4 | 8.12 | 5.99 | 12.4 | 14.25 | 3050 | 1.18 |

| 80HP | 1″ | 25.4 | 15.88 | 15.88 | 20.8 | 24 | 3.1 | 3.1 | 11.27 | 8.02 | 16.3 | 17.75 | 5800 | 2.1 |

| 08BHP | 1/2″ | 12.7 | 7.75 | 8.51 | 10.6 | 11.8 | 1.5 | 1.5 | 6.11 | 4.5 | 8.2 | 9.3 | 1500 | 0.63 |

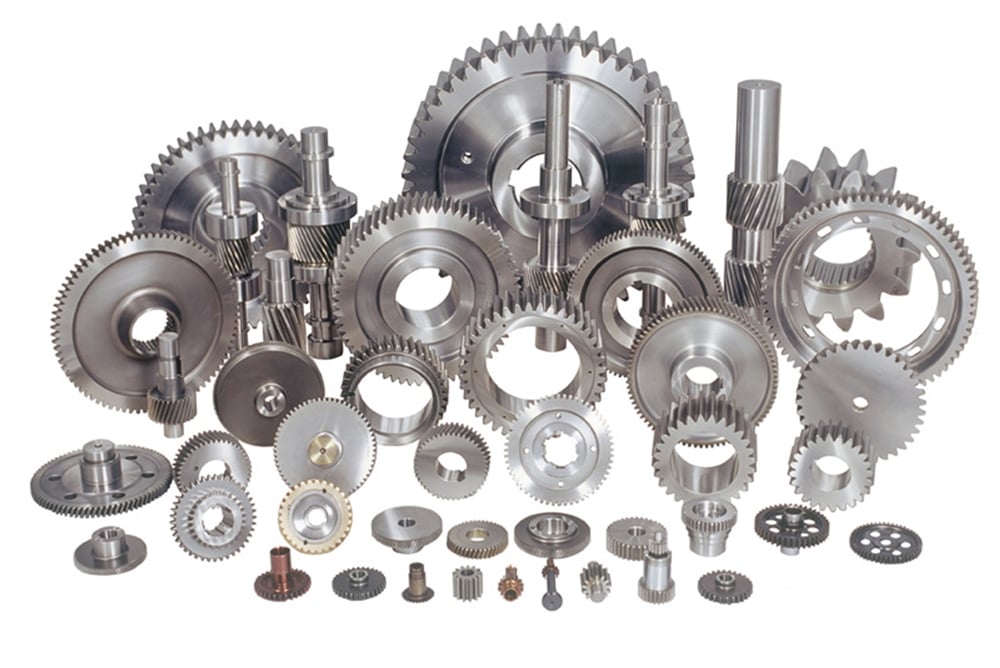

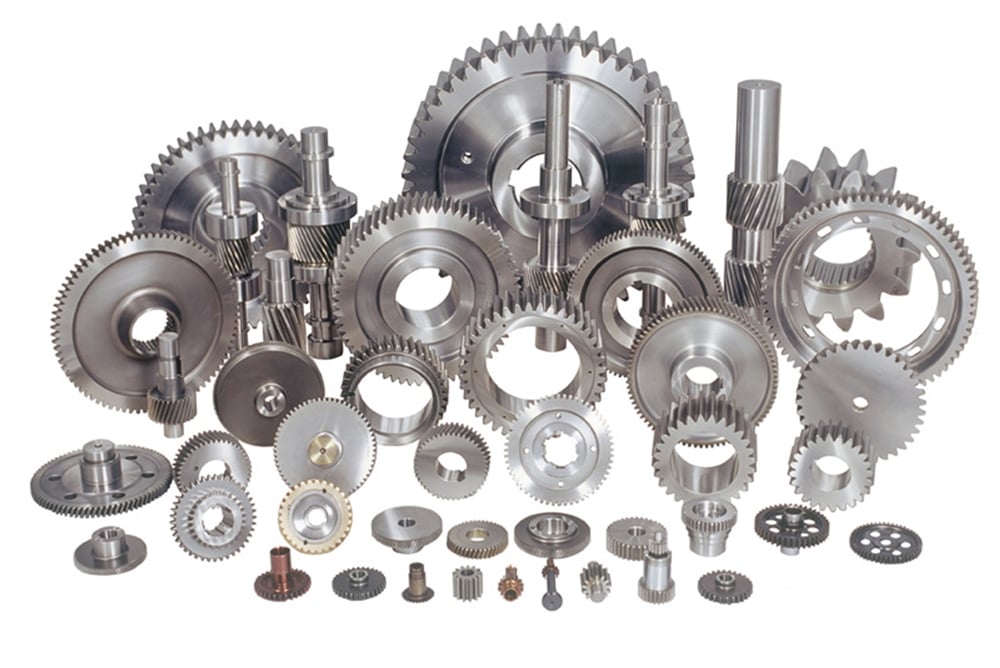

china supplier Poly Chain Gt 2 Timing Belt Pulley manufacturers

Merchandise Description

CZPT CZPT ry provides a wide range of high top quality Timing Belt Pulleys and Toothed Bars / Timing Bars. Common and CZPT -normal pulleys according to drawings are CZPT .

Sorts of substance:

1. AlCuMgPb 6061 6082 CZPT Timing Pulley

2. C45E 1045 S45C Carbon Steel Timing Pulley

3. GG25 HT250 Forged Iron Timing Pulley

4. SUS303 SUS304 AISI431 CZPT Steel Timing Pulley

5. Other substance on need, such as cooper, bronze and plastic

Varieties of area therapy

1. Anodized surface area -Aluminum Pulleys

2. Hard anodized area — Aluminum Pulleys

3. Black Oxidized surface — Steel Pulleys

4. Zinc plated surface area — Steel Pulleys

5. Chromate surface — Steel Pulleys Forged Iron Pulleys

6. Nickel plated area –Metal Pulleys Cast Iron Pulleys

Sorts of tooth profile

| Enamel Profile | Pitch |

| HTD | 3M,5M,8M,14M,20M |

| AT | AT5,AT10,AT20 |

| T | T2.5,T5,T10 |

| MXL | .08″(2.032MM) |

| XL | one/5″(5.08MM) |

| L | three/8″(9.525MM) |

| H | one/2″(12.7MM) |

| XH | 7/8″(22.225MM) |

| XXH | 1 1/4″(31.75MM) |

| STS STPD | S2M,S3M,S4.5M,S5M,S8M,S14M |

| RPP | RPP5M,RPP8M,RPP14M,RPP20M |

| PGGT | PGGT 2GT, 3GT and 5GT |

| PCGT | GT8M,GT14M |

Varieties of pitches and dimensions

Imperial Inch Timing Belt Pulley,

1. Pilot Bore MXL571 for 6.35mm timing belt tooth quantity from sixteen to 72

two. Pilot Bore XL037 for 9.53mm timing belt teeth amount from 10 to seventy two

three. Pilot Bore, Taper Bore L050 for twelve.7mm timing belt tooth quantity from 10 to 120

four. Pilot Bore, Taper Bore L075 for 19.05mm timing belt teeth amount from ten to a hundred and twenty

five. Pilot Bore, Taper Bore L100 for 25.4mm timing belt tooth number from ten to 120

six. Pilot Bore, Taper Bore H075 for 19.05mm timing belt tooth number from 14 to 50

seven. Pilot Bore, Taper Bore H100 for 25.4mm timing belt teeth amount from 14 to 156

eight. Pilot Bore, Taper Bore H150 for 38.1mm timing belt enamel amount from 14 to 156

nine. Pilot Bore, Taper Bore H200 for 50.8mm timing belt tooth amount from 14 to 156

ten. Pilot Bore, Taper Bore H300 for 76.2mm timing belt teeth variety from 14 to 156

eleven. Taper Bore XH200 for 50.8mm timing belt teeth variety from 18 to a hundred and twenty

12. Taper Bore XH300 for 76.2mm timing belt enamel amount from eighteen to one hundred twenty

thirteen. Taper Bore XH400 for 101.6mm timing belt teeth number from 18 to 120

Metric Timing Belt Pulley T and AT

one. Pilot Bore T2.5-16 for 6mm timing belt teeth quantity from twelve to 60

2. Pilot Bore T5-21 for 10mm timing belt tooth quantity from 10 to 60

three. Pilot Bore T5-27 for 16mm timing belt tooth quantity from 10 to 60

four. Pilot Bore T5-36 for 25mm timing belt tooth amount from 10 to 60

5. Pilot Bore T10-31 for 16mm timing belt tooth quantity from 12 to 60

six. Pilot Bore T10-40 for 25mm timing belt tooth amount from 12 to 60

7. Pilot Bore T10-47 for 32mm timing belt enamel variety from eighteen to 60

eight. Pilot Bore T10-66 for 50mm timing belt enamel quantity from 18 to 60

9. Pilot Bore AT5-21 for 10mm timing belt tooth number from twelve to 60

10. Pilot Bore AT5-27 for 16mm timing belt enamel number from twelve to sixty

11. Pilot Bore AT5-36 for 25mm timing belt tooth amount from twelve to 60

12. Pilot Bore AT10-31 for 16mm timing belt tooth number from fifteen to 60

thirteen. Pilot Bore AT10-40 for 25mm timing belt teeth variety from fifteen to 60

14. Pilot Bore AT10-47 for 32mm timing belt tooth variety from 18 to 60

fifteen. Pilot Bore AT10-66 for 50mm timing belt teeth variety from 18 to sixty

Metric Timing Belt Pulley HTD3M, 5M, 8M, 14M

1. HTD3M-06 3M-09 3M-15 teeth quantity from ten to 72

two. HTD5M-09 5M-fifteen 5M-25 tooth quantity from 12 to 72

3. HTD8M-twenty 8M-30 8M-50 8M-85 teeth variety from 22 to 192

four. HTD14M-forty 14M-55 14M-eighty five 14M-a hundred and fifteen 14M-a hundred and seventy tooth amount from 28-216

5. Taper Bore HTD5M-fifteen 8M-20 8M-30 8M-50 8M-85 14M-forty 14M-fifty five 14M-85

14M-one hundred fifteen 14M-170

Metric Timing Belt Pulleys for CZPT Chain GT2 Belts

1. PCGT8M-twelve PCGT8M-21 PCGT8M-36 PCGT8M-62

two. PCGT14M-20 PCGT14M-37 PCGT14M-68 PCGT14M-90 PCGT14M-one hundred twenty five

Electricity Grip CZPT Tooth/ PGGT 2GT, 3GT and 5GT

1. 2GT-06, 2GT-09 for timing belt width 6mm and 9mm

2. 3GT-09, 3GT-15 for timing belt width 9mm and 15mm

three. 5GT-fifteen, 5GT-25 for timing belt width 15mm and 25mm

OMEGA RPP HTD Timing Pulleys

1. RPP3M-06 3M-09 3M-15 teeth variety from ten to 72

2. RPP5M-09 5M-fifteen 5M-twenty five enamel quantity from 12 to 72

3. RPP8M-20 8M-thirty 8M-fifty 8M-85 teeth quantity from 22 to 192

4. RPP14M-40 14M-fifty five 14M-85 14M-a hundred and fifteen 14M-170 tooth quantity from 28-216

five. Taper Bore RPP5M-15 8M-twenty 8M-30 8M-fifty 8M-85 14M-forty 14M-55 14M-85

14M-a hundred and fifteen 14M-a hundred and seventy .

Ubet CZPT ry is also competetive on these CZPT transmission elements.

AC motors are also diverse from DC motors due to the fact most AC motors do not include brushes. This signifies that routine maintenance and components alternative requirements for AC motors tend to be substantially lowered, with most end users typically expecting a longer typical lifespan. Unlike DC motors, the output speed of many kinds of AC motors is typically decided by inverter manage – once more, we are going to briefly outline a assortment of potential versions on the basic AC motor product.

China Chain and sprocket factory : Food roller blinds chain price China in Tanta Egypt Grade Conveyor Roller Modular Belt Double Limited Tablet Hairise 900 with ce certificate top quality low price

We – EPG Team the most significant Chain and agricultural gearbox factory in China with 5 distinct branches. For more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

If you want any information or samples, make sure you contact us and you will have our quickly reply.Company EPG has been effectively certified by ISO9002 High quality Administration Method, ISO9001 Good quality Management Technique, API certification, ISO/TS16949:2002 and ISO10012 measurement management system. of common and custom roller chains. Suited for getting older, anxiety relieving, heat managing and powder coating programs. Aerospace, automotive, army, power, composite, pharmaceutical and a variety of other industries served. Turnkey programs integration and most objects accessible in stock. ISO 9001:2000 & AS 9100B licensed personalized manufacturer of roller chains. Technical specs of roller chains contain .1475 in. to .3750 in. pitch, 5.9 in. to 35.4 in. duration, a hundred and eighty lbs. to 1529 lbs. tensile load potential & .035 lbs. to .276 lbs. bodyweight/ft. Foodstuff Quality EPT Roller Modular belt Double Minimal Tablet EPT 900

one.Model:Har900 Series

2.Pitch:twenty five.4mm

three.Thickness:8.8mm

four.Situation:New

five.POM loading bearing:21500N/M

PP loading bearing:15710N/M

6.Structure:Modular belt

seven.StHangZhourd:ISO9001:2008

8.Area:ZheJiang , China

nine.Markets:Worldwide

ten.Attribute:High efficiency

11.Applications:Food & Beverage & Cartons & industry items conveying

Merchandise present:

Special Features:

Material:POM / PP

ISO9001:2008

Use-resisting

Oil & cut resistance

Substantial temperature resistant

Non-stick

Lower coefficient of friction on top facet and bottom aspect

Oil skimmer belts are offered in stock

Proportions as for each intercontinental stHangZhourds.

With ultrasonically welded middle guide

Ultrasonically welded Aspect wall and lateral cleats as per buyer specifications.

Fingure joint, FOF Joint, Overlap Joint, and Mechanical fastener joint.

Software:

Our items are broadly used in standard conveyance and packaging traces.

* Foods, delicate beverages applications

* Packaging&Can, Bottle transfering

* Pulses and granular merchandise

* Various DIP tank apps

* Tobacco, medication&chemical business

* Electronics, Auto: +86~13083988828s and logistics, and so forth

Advantage:

1.Customized goods approved, we can make items according to your demands.

2.High good quality services and historic track record

three.Reduced price with superior top quality and large efficiency

four.Very good deal,safe and rapid shipping.

Supply Time:

Material Preparing Time:1 day

Processing Time:5 times

Assembly & Packaging Time:1 working day

Overall Shipping Time:7 days in 100sq.Meters for secure shipping and delivery lead time.

The quicker shipping could be negotiable.

Associated Products:

| Plastic tabletop conveyor chain | EPT technique | Sprockets |

| Multiflex plastic conveyor chains | Plastic modular belt | Plastic transfer plate |

| EPT connection elements | EPT Rollers | Stainless metal conveyor chains |

Company Details:

ZheJiang EPT Transmission Equipment Shares Co.,Ltd

Mujia EPT Technological innovation (ZheJiang ) Company Limited

Fir EPT Shown Company In China EPT Market

China’s Huge EPT EPT Add-ons Supplier

ZheJiang All-ka Transmission Equipment is an built-in company affianced in

Company&innovations,layout,assemble&sale of automation tools throughout the world

I.E.Conveyor,modular belt,leading chains,versatile chains and conveyor spare parts.

FAQ:

one.Q:How lengthy is your shipping time?

A:Normally it is 2-3 times if the goods are in stock.Or it is fifteen-twenty times if the merchandise are not in inventory, it is according to amount.

two.Q:Do you provide samples ?Is it totally free or added ?

A:Sure, we could provide the sample for cost-free demand but do not spend the co EPT of freight.

3.Q:I don’t know what belt I currently use.Can you assist me identify my belt?

A:Our online belt identifier can aid you narrow down the collection and design of your recent belt.If you require much more specific data on plastic conveyor chain, make contact with me freely for any plastic conveyor chain.

four.Q:What can you do If the merchandise have been broken?

A:(1.)If merchandise were damaged when you purchased from me,I would substitute them freely for plastic conveyor chain.

(2.)If the items were damaged when you employed,We could give 1 year quality ensure for plastic conveyor chain under widespread functioning environment.

Contact us:

Welcome to pay a visit to our manufacturing facility and prepared to contact us if you want any more assistance ahead of or soon after revenue.

The use of original equipment manufacturer’s (OEM) part quantities or emblems , e.g. CASE® and John Deere® are for reference purposes only and for indicating item use and compatibility. Our business and the detailed substitution areas contained herein are not sponsored, approved, or created by the OEM.

China Chain and sprocket factory : Agricultural conveyor chain with plastic rollers in Ibadan Nigeria Steel Pintle Conveyor Chain with ce certificate top quality low price

We – EPG Team the most significant Chain and agricultural gearbox manufacturing unit in China with 5 diverse branches. For far more details: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

It has established secure cooperation with a lot of effectively recognized universities and institutes in china this kind of as, Zhejiang University, Jilin College, Technological committee of national chain push regular, Institute of national chain travel, Zhejiang software engineering material institute, Huhan substance protection institute and it cooperated to identified China Initial Car chain institute with Countrywide chain drive institute.One particular EPG is a single of the most significant manufacturers in China. We have advanced devices for creation and new technological innovation tests capability . Through adopting new technologies from British, German, U.S.A, our products are greatest sellers all over European, The usa, and Southeast Asia.factor of our software consulting is that we have been gathering and combining the knowledge in chain and sprocket purposes in various regions for a long time. This is especially exciting for us whenever consumers technique us with some exceeding and tough specifications. ISO 9001:2000 certified. Stocking distributor of electrical power transmission goods such as roller & multiple strand roller chains. Products also include brakes, generate elements, gears, torque limiters, U-joints, pulleys, sheaves, encoders, belt drives, clutches & motors are also accessible. Agricultural Steel Pintle EPT Chain (667H)

Metal Pintle Chain Is Appropriate For Driving, Transmission And EPT Machine In Medium Low Speed,

Medium Minimal Loading, It Can Also Perform In The Smudgy Atmosphere.

Chain No.

662

667X

667H

667J

667K

88K

We possess the advanced tools and the sophisticated engineering, this sort of as:

1. C EPT Designer

2. Wire Cutting Device

three. Chain Managing In Machine

four. EPT Furance

five. Ball Drift

6. Shot Peened Areas

7. Design Of Hyperlink Plate Waist

Pack Depth:polybag+box+case

Company Element:

EPT is a single of a skilled exporter with exporting Electrical power TRANSMISSION Components: Roller chains,conveyor chains,Stainless steel Chains, agricultural chains, metal removable chains, unique chains, sprockets, s. S. Sprockets, HRC couplings, pulleys, bushes and many others. All these merchandise have been equipped often to Globe Wide for in excess of fifteen many years.

Welcome contact for far more information.

EPT Gao(Income)

Tran-Auto Industries Co.,Minimal

716 Gold River Middle,NO.88 Shishan Rd.,

EPT District,HangZhou,P.R.China.P.C.:215011

Cell: +86~13083988828:-512-65830037/15862544283

Fax:-512-65529992

| Chain No | Pitch | Supreme tensile toughness | Weight |

| mm | KN | kg/m | |

| 205 | 31.75 | 12.5 | .58 |

| 662 | 42.27 | 37.8 | one.six |

| 667X | 57.fifteen | 66.seven | 3.thirteen |

| 667H | 58.75 | forty two.26 | 1.seven |

| 667J | fifty seven.fifteen | 62.28 | two.7 |

| 667K | 57.15 | 108.ninety nine | 3.94 |

| 667XH | fifty seven.fifteen | 124.six | four.48 |

| 88K | sixty six.27 | 108.ninety nine | 3.ninety one |

| 308C | 78.11 | 222.forty two | nine.8 |

The use of original gear manufacturer’s (OEM) portion figures or emblems , e.g. CASE® and John Deere® are for reference purposes only and for indicating merchandise use and compatibility. Our business and the outlined substitute areas contained herein are not sponsored, accredited, or created by the OEM.

Duplex near me shop made in China – replacement parts – in Tepic Mexico Short Pitch Precision Roller Chain Chain with top quality

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For a lot more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

XIHU (WE EPT LAKE) DIS. EPT Chain Group is the mo EPT specialist company of power transmission in China, manufacturing roller chains, industry sprockets, bike sprockets, casting sprockets, diverse sort of couplings, pulleys, taper bushes, locking devices, gears, shafts, CNC precision elements and so on. We have passed ISO9001, ISO14001, TS16949 such high quality and enviroment certification

We undertake great high quality raw materials and rigid with DIN, ANSI, JIS common ect, We have specialist high quality conrol group, complet products, advanaced engineering. In 1999, Xihu (We EPT Lake) Dis.hua acquired ISO9001 Certificate of Good quality Assurance Program, aside from, the company also devotes itselt o environmental protection, In2002, it also received ISO14001 Certificate of Environment Administration System.

Brief pitch precision roller chains (A collection) 15-240 simlex to eightlex includ regular short pitch precisson roller chains and large obligation sequence roller chains

Brief pitch precision roller chains (B series) 04B-72B simlex to triplex includ regular quick pitch precisson roller chains and hefty duty series roller chains

Short PITCH PRECISSION ROLLER CHAINS (A Series)

Substance: Alloy Steel

Surface Therapy: Shot Peening / Blacking / Blueing

Main Software: Idustry equipment

| Product name | Duplex Short Pitch Precision Roller Chain (A collection) Chain (DIN764) |

| Materials Available | 1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420 |

| 2. Steel:C45(K1045), C46(K1046),C20 | |

| three. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40) | |

| 4. Bronze: C51000, C52100, C54400, etc | |

| five. Iron: 1213, 12L14,1215 | |

| six. Aluminum: Al6061, Al6063 | |

| seven.OEM according to your request | |

| Surface area Therapy | Annealing, natural anodization, heat treatment, polishing, nickel plating, chrome plating, znic plating,yellow passivation, gold passivation, satin, Black floor painted etc. |

| Products Available | sprockt chains, pulley, shafts(axles, spline shafts, dart shafts),gears (pinions, wheels gear rack) bearing, bearing seat, bushing, coupling, lock assembly and so on. |

| Processing Method | CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly |

| QC : | Technicians self-check in production,closing-check prior to package by skilled High quality inspector |

| Size | Drawings |

| Bundle | Wood Circumstance/Container and pallet, or as per customized specifications |

| Certification | ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009 |

| Edge | High quality fir EPT Support exceptional , Innovative gear,Experienced workers, EPT tests gear |

| Lead Time | fifteen-25days samples. 30-45days offcial order |

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing facility in China with 5 different branches. For far more information: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of original equipment manufacturer’s (OEM) element quantities or trademarks , e.g. CASE® and John Deere® are for reference needs only and for indicating merchandise use and compatibility. Our business and the outlined replacement elements contained herein are not sponsored, approved, or made by the OEM.

China manufacturer & factory supplier for China in Guadalajara Mexico manufacturer LH1634 Industrial Leaf Chain With high quality best price & service

EPG is a foremost provider of large high quality, value-effective energy transmission parts. As our item strains continue to increase to satisfy our customer’s wants, our dedication to personalized consumer support and on-time shipping and delivery continues to be next to none.A lot more importantly, we make specific elements in accordance to provided drawings/samples and warmly welcome OEM inquiries.

Overview

Rapid Details

- Relevant Industries:

-

Creating Substance Stores, Production Plant, Equipment Fix Stores, Food & Beverage Factory, Farms, Construction works , Power & Mining, agricultural machiner

- Item title:

-

LH1634 (BL1634) Industrial Leaf Chain

-

RV025~RV150 Sound Shaft Input RV025~RV150 Functions: 1. Good quality aluminum alloy equipment box, light fat and not rust 2. 2 optional worm wheel materials: Tin (Stannum) bronze or aluminum bronze alloy 3. Standard areas and really adaptable for shaft configurations and motor flange interface 4. Several optional mounting alternatives 5. Reduced sound, High efficiency in heat dissipation

- Plates lacing:

-

2×2, 2×3, 3×4, 4×4, 4×6 and many others

- Operation requirement:

-

Great lubrication, below standard managing circumstances

- Software:

-

Fork Lifts/Hoist

- Surface area Therapy:

-

Shot Blasting

- Pitch:

-

twelve.7mm

- Pin diameter:

-

5.09mm

- Plate thickness:

-

two.08mm

Source Potential

- Source Potential:

- 10000 Meter/Meters for every Month

Packaging & Shipping

- Packaging Details

- Chain+Plastic Bag+Neutral Box+Picket Situation

- Port

- Tianjin/Shanghai/Qingdao

Online Customization

LH0822 (BL422) Industrial Leaf Chain

one. Kind: Leaf Chain

2. Material: Stainless steel,Alloy steel,40Mn

3. Software: Fork Lifts/Hoist

4. We are factory

five. Tiny get be accepted

We can offer all sorts of conveyor roller chain and matched sprockets. We have big amount in inventory. We can also create all types of non-standard roller chain according to your drawing.

|

ISO Chain N0. |

ANSI Chain N0. |

Pitch |

Chain Lacing |

Plate depth |

Plate thickness |

Pin diameter |

Pin duration |

Supreme tensile power |

Average tensile power |

| P |

h2 max |

T max |

d2 max |

L max |

Q min |

Q0 | |||

| mm | mm | mm | mm | mm | kN/LB | kN | |||

| LH0822 | BL422 | 12.7 | 2X2 | 12.07 | 2.08 | 5.09 | 11.If you are searching for a 540 PTO shaft, 540 to one thousand PTO adapter, 540 PTO hydraulic pump, or a 540 PTO gearbox, appear no further. It is critical to replace PTO elements that are worn or cracking before you have a key breakdown that could be costly and even harmful. We have PTO generate shafts as nicely as crucial protect areas for your security. Our Eurocardan elements incorporate a range of varieties of clutches to improve the operation of your energy just take-off method. PTO shafts and equipment are an crucial component of the a lot more than 26,000 products we carry for farm, shop, house and backyard garden.05 | 22.2/5045 | 27.6 |

| LH0823 | BL423 | 2X3 | 13.sixteen | 22.2/5045 | 27.6 | ||||

| LH0834 | BL434 | 3X4 | 17.40 | 33.4/7591 | 41.four | ||||

| LH0844 | BL444 | 4X4 | 19.fifty one | 44.5/10114 | 56. | ||||

| LH0846 | BL446 | 4X6 | 23.seventy five | 44.5/10114 | 56. | ||||

| LH0866 | BL466 | 6X6 | 27.ninety nine | 66.7/15159 | 81.seven | ||||

| LH0888 | BL488 | 8X8 | 36.45 | 89./20227 | 109.four | ||||

| LH1022 | BL522 | 15.875 | 2X2 | 15.09 | 2.forty four | 5.96 | 12.nine | 33.4/7591 | 43.1 |

| LH1023 | BL523 | 2X3 | 15.37 | 33.4/7591 | 43.1 | ||||

| LH1034 | BL534 | 3X4 | 20.32 | 48.9/11114 | 65.6 | ||||

| LH1044 | BL544 | 4X4 | 22.seventy eight | 66.7/15159 | 84.five | ||||

| LH1046 | BL546 | 4X6 | 27.seventy four | 66.7/15159 | 84.5 | ||||

| LH1066 | BL566 | 6X6 | 32.69 | 100.1/22750 |

125.1 |

||||

| LH1088 | BL588 | 8X8 | 42.57 | 133.4/30318 | 169.five | ||||

| LH1222 | BL622 | 19.05 | 2X2 | 18.11 | 3.three | 7.ninety four | 12.seventy three | 48.9/11114 | 63.6 |

| LH1223 | BL623 | 2X3 | 20.73 | 48.9/11114 | 63.six | ||||

| LH1234 | BL634 | 3X4 | 27.43 | 75.6/17181 | 102.8 | ||||

| LH1244 | BL644 | 4X4 | 30.78 | 97.9/22250 | 120.nine | ||||

| LH1246 | BL646 | 4X6 | 37.forty nine | 97.9/22250 | 120.nine | ||||

| LH1266 | BL666 | 6X6 | 44.20 | 146.8/33364 | 190.8 | ||||

| LH1288 | BL688 | 8X8 | 57.sixty one | 195.7/44477 | 238.8 | ||||

| LH1622 | BL822 | 25.four | 2X2 | 24.thirteen | 4.09 | 9.fifty four | 21.34 | 84.5/19204 | 108.two |

| LH1623 | BL823 | 2X3 | 25.48 | 84.5/19204 | 108.2 | ||||

| LH1634 | BL834 | 3X4 | 33.seventy six | 129./29318 | 170. | ||||

| LH1644 | BL844 | 4X4 | 37.ninety | 169./38409 | 214.6 | ||||

| LH1646 | BL846 | 4X6 | 46.18 | 169./38409 | 214.6 | ||||

| LH1666 | BL866 | 6X6 | 54.46 | 253.6/57636 | 324.five | ||||

| LH1688 | BL888 | 8X8 | 71.02 | 338.1/76841 | 432.seven |

Usuallu utilised the suitable for transportation by sea, rail, air, and other suited for import and export customs clearance of free fumigation picket box of free fumigation picket pallets (precision merchandise employed the collision coating layer in the packaging box, to guarantee the merchandise protected adequate).

Remarks:

All things are checked and examined totally during every operating method, and after the item is ultimately created to make certain that the greatest good quality merchandise enter into the market.

Exhibition

China Chain and sprocket factory : Clamping chain for replacement of renold conveyor chain catalogue in Stuttgart Germany Ring Barrel Hoop Roll Forming Machine with ce certificate top quality low price

We – EPG Team the biggest Chain and agricultural gearbox manufacturing unit in China with 5 diverse branches. For more information: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

With numerous years’ knowledge in this line, we will be dependable by our advantages in competitive cost, one-time shipping, prompt reaction, on-hand engineering assistance and great soon after-product sales solutions.Moreover, all our generation procedures are in compliance with ISO9001 standards. EP The large specific CNC gear, such as Sluggish-feeding wire-minimize device, jig grinding equipment and electric powered discharge equipment, makes certain the prime good quality precision of mould processing, with the substantial effective and environmental protection acid rolling line getting the greatest raw substance converting equipment in the field in china The wildly use of computerized milling device, higher-velocity automatic feeding punch, higher velocity automated rolling and assembling device assures the high good quality and efficiency of components and chain making. Group has increased its business lines to contain Electricity Transmission Units and Components, Automotive Elements and Components Dealing with Techniques. First of all: modern merchandise engineering. We are continually strengthening effectively-established and recognized merchandise in the places of generate and conveyance technology or are searching for attainable innovations. 1 illustration for this is the routine maintenance-free chain. Secondly: outstanding generation engineering. Our production processes are also continuously improved upon. Very usually successful, new products are only achievable due to the fact of progressive creation approaches. Thirdly: qualified application consulting.

Clamping Ring Barrel Hoop Roll Forming Machine

Type: High-precision information column bracket equipment chain drive(inverter motor control)

Perform and composition: sheet will from by way of 8 rollers, and steadily roll into the finished bracket. By the variable frequency motor, reducer, equipment, roller group composition. The lathe with welded framework, to pressure remedy

The roller adopts the mixture framework, the speed distinction and the forming resistance are modest, the metal surface area use is tiny the roll approach design and style employs the imported application, the personal computer style, and carries on the FEA examination, guarantees the piece condition precision, does not scratch the sheet materials. Roller with Cr12MoV forging, the all round quenching CNC machining, hardness uptoHRC58-sixty two with high toughness, large hardness, high precision, using life and so on.

Rapid adjust composition

Move pitch: 200mm

Rack:Precision information column bracket

Roll shaft diameter:45mm

Material: 42CrMo

| No | Equipment Name | Amount |

Motor Electricity (KW)

|

| one | Automatic Uncoiler | 1 set | 3 |

| 2 | Exact Leveling Equipment | 1set | 1.five |

| three | Roll Forming Equipment | 1set | 15 |

| 4 | Bending, Reduce Off | 1set | 5 |

| No | Product | Manufacturer |

| 1 | Plc | Omron |

| 2 | Hmi | Omron |

| three | Electric Aspects | Schneider/Omron Keyence/ Siko |

| four | Bearing | Timken,Schaeffler |

| five | Variable Frequency Motor | Siemens |

| six | Rotary Encoder | Omron |

| 7 | Electronic Situation Display | Siko |

FAQ

1.Q: Are you maker or investing business?

A: We are manufacture and investing company.

two.Q:What details you need to have prior to you make the proposal?

A:The pipe diameter and thickness assortment which you need to have or the profile drawings, content information, your special demands.

3.Q: what is the MOQ?

A: A single established

4.Q: Do you provide installing and debugging abroad?

A: Abroad equipment install and worker instruction providers are optional.

five.Q: Can you make the device in accordance to my design and style or prototype?

A: Yes, we have an skilled group for doing work out the mo EPT appropriate design and style and creation prepare for the machine that you are going to ebook with us.

6.Q: How does your factory do concerning top quality manage?

A :There is no tolerance concerning quality handle. Quality manage complies with ISO 9001.each equipment has to pa EPT tests running before it really is packed for shipment.

seven.Q: How can I tru EPT you that machines pasted screening working prior to transport?

A: 1) We record the testing video clip for your reference

two) We welcome you visit us and te EPT machine by by yourself in our manufacturing unit.

8.Q: What about our right after-sale service?

A: we provide technical support on line as well as overseas companies by skillful technicians.

nine.Q: What must I do if I ju EPT begin a new company?

A:Speak to us immediately ,we give free of charge specialist pre-product sales services.Also we can help you to remedy the substance(metal coil)obtain,worker prepare,worldwide marketplace value.

10. Q:Can I pay a visit to you manufacturing facility to check out machines on-web site ? What Ought to I deliver when I check out your manufacturing unit?

A: We are maker, and we welcome consumers to visit our factory. For unique item design and style and produce, we reque EPT you deliver a piece of tests material, you can te EPT on our machines on-internet site.

The use of original tools manufacturer’s (OEM) element figures or trademarks , e.g. CASE® and John Deere® are for reference needs only and for indicating product use and compatibility. Our company and the listed alternative elements contained herein are not sponsored, accredited, or made by the OEM.